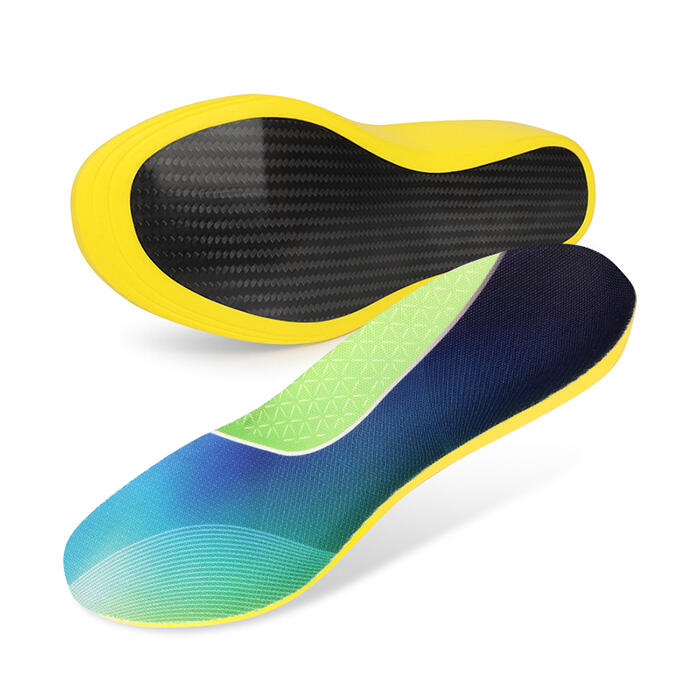

insoles manufacturer

As a leading insoles manufacturer, we combine cutting-edge technology with expert craftsmanship to produce premium quality insoles that meet diverse customer needs. Our state-of-the-art manufacturing facility employs advanced materials science and precision engineering to create ergonomically designed insoles that provide superior comfort and support. We utilize innovative production techniques, including computer-aided design and automated manufacturing processes, to ensure consistent quality across our product range. Our comprehensive quality control system monitors every stage of production, from raw material selection to final product inspection. The facility is equipped with specialized testing equipment to evaluate durability, shock absorption, and pressure distribution. We offer customization options to meet specific requirements, whether for orthopedic purposes, athletic performance, or everyday comfort. Our research and development team continuously works on improving existing products and developing new solutions, incorporating feedback from healthcare professionals and end-users. The manufacturing process adheres to international quality standards and environmental regulations, ensuring sustainable and responsible production practices.